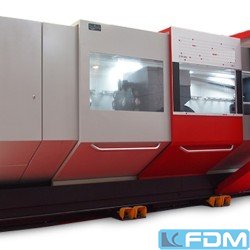

CNC Lathe

SMTCL CAK6163D

- Stock number:

- 1124-100331

- Year / Condition:

- 2005 / Used machine

- Control unit:

- CNC (Fanuc 0i TC mate)

- Country of origin:

- China

- Freight basis:

- ex stock, free on truck

- Item location:

- North-Italy

- Delivery time:

- ex stock

Picture / documents / videos

Technical specs

Details

- turning diameter:

- 630 mm

- turning length:

- 2850 mm

- control:

- Fanuc 0i-mate MGI

- swing diameter over slide rest:

- 350 mm

- bed width:

- 550 mm

- spindle nose:

- D11/1:20

- spindle bore:

- 104 mm

- spindle speeds::

- 17-1000 U/min

- transmission ratio:

- autom. 4-stufig

- rapid power traverse in X-and Z direction:

- 4/8 m/min

- tailstock quill taper MT:

- 5 Morse

- Quill travel:

- 200 mm

- diameter of quill:

- 100 mm

- workpiece accuracy:

- 6-7 ITF

- x-travel:

- 320 mm

- z travel:

- 3000 mm

- chuck size:

- 315 mm

- dimensions:

- 5200 x 1900 x 1900 mm

- 6 t

- power capacity:

- 11 kW

Accerories

- CNC controller:

- FANUC 0i mate TC

- 3 jaw chuck Ø:

- 315

- technical documentation in German language

- hydr. tailstock quill movement

- steady rest:

- 2 Stück

- coolant system

- align center

- Tools

- live center

- center sleeve

- frequency control main spindel engine:

- 11 kW

- central lubrication

- CE-design

- workshop light

- turret:

- 8-fach

- hydraulic unit

- MPG hand wheel

- Machine semi-cover

Description

Flat Bed CNC Lathe

Flat Bed CNC Lathe, CAK63/80 Series

CAK 63/80 series CNC lathes integrate proven structure, stable functionality, and reliable quality to make an economical, practical, universal machine. They are widely used in such industries as automotive, petroleum, military, among others. They are the preferred lathe among customers in China.

This series of machine tools can be used in a wide range of applications, and can machine inside or outside surfaces of shaft-type work-pieces and disc-type workpieces, curved surfaces, arcs, threads, bores, and reaming holes, among other things. Various CNC systems and accessories can be provided according to the needs of the customer.

This series of CNC lathes have horizontal flat-vee hardened guide-ways, with the undersides of slides coated with TSF anti-friction material, for flexible operation and stable and reliable accuracy.

Key parts of the lathes are all hardened, and are designed to provide good rigidity to the cutting operation.

The main motor is the variable-frequency (inverter) type, and this is combined with automatic hydraulic range change which allows any range of speed to be programmed.

The tool turret is of the Hirth-style coupling type, which means that positioning of the tool-post in a rotary axis is accurate and repeatable.

The feed system uses ball-screws with high accuracy drives and directly-coupled motors to eliminate error due to backlash of screws, gears or belts.

The flat bed CNC lathe integrates mechanical, hydraulic, and electrical/control systems in a sleek, compact design.

Because of its modular design, many different configurations can be selected by the end-user. Internationally-recognized control systems can be selected by the customer, such as FANUC, SIEMENS, SMTCL-NC-100, etc.

Available tool-post configurations include vertical 4-station, vertical 6-station, and horizontal 6-station.

Guarding is available either for semi-enclosed or fully-enclosed configurations. Manual or hydraulic chucks, and manual or hydraulic tail-stock options are available.

Maximum turning diameter of parts is 630 mm. (CAK 63 series) or 800 mm. (CAK 80 series). Each series has a full complement of standard and available accessories and equipment.

For machines whose maximum machining length is 1350 mm. or less, no steady or follower rests are provided. For machines whose maximum machining length is 2850 mm. or greater, roller-style rests are provided.

Contact seller

GK Werkzeugmaschinen GmbH

Lindenstr. 2164589 Stockstadt Phone: + 49 (0) 61 58/8 47 72Fax: +49 615886931