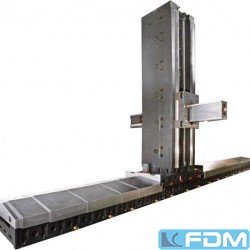

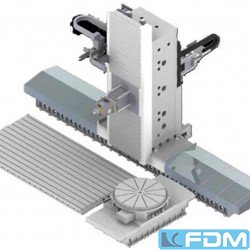

Floor Type Boring and Milling M/C - Hor.

KRAFT FBM-160

- Stock number:

- 1124-97200

- Year / Condition:

- Fabrikneu / Neu

- Control unit:

- CNC (Siemens/Fanuc/Heidenhain)

- Country of origin:

- Taiwan

- Freight basis:

- FOB Taiwan

- Item location:

- Taiwan

- Delivery time:

- 5 - 7 month after sales confir

Picture / documents / videos

Technical specs

Details

- spindle diameter:

- 160 mm

- x-travel:

- 4000/6000/8000/10000/12000/14000/16000 mm

- y-travel:

- 2000/2500/3000/3500/4000 mm

- z-axis:

- 1200 mm

- w-axis:

- 700 mm

- spindle cone:

- 50 SK/BT

- spindle speed max.:

- 3000 U/min

- spindle drive:

- 37/51 kW

- feeds:

- X/Y/Z/W: 10 / 10 / 10 / 8 / 5 m/min

- rapid speed:

- X/Y/Z/W: 20 / 20 / 20 / 10 / 5 m/min

- max. torque on the spindle:

- 3.300 Nm

- cross section of ram:

- 460x520 mm

- table load:

- 30 t

- table-size:

- 2500x2500 mm

- table travel:

- 1500 mm

- weight of the machine ca.:

- FBM-160 mit X=4m: 80 t

- positioning accuracy:

- 0.032/1000 mm

- repeating accuracy:

- 0.018/1000 mm

Accerories

- CNC controller:

- Siemens/Fanuc/Heidenhain

- CE-design

- European electric

- ball screw in axes

- spindle bearing

Description

Factory-new CNC controlled panel drilling machine with CNC control from Siemens / Fanuc / Heidenhain. All essential components from well-known manufacturers such as Siemens, SKF, FAG, Heidenhain, Igus and many more.

Newly developed FB series

Convenient for a variety of manufacturing applications

Modular arrangement

With a variety of options for even greater productivity and application diversity

Machine layout:

· Extra-wide flat guides with heavy-duty roller guides for heavy-duty machining

· High table loadability

· High-precision table

Spindle:

· Highly accurate and highly rigid spindle pair from SKF

· Constant temperature oil cooling and thermal spindle compensation system

· Optimized span to ensure a rigid spindles system

· Removable spindle sleeve

Stand:

· High-quality sand-based cast iron from our own foundry

· Double thermal aging for stable precision

· The FEA optimization design ensures high stiffness

· Wide guide rails for heavy milling and drilling operations

· Large cross-section column

Machine bed:

· Heavy machine bed from our own foundry

· Double thermal aging for stable precision

· The FEA optimization design ensures high stiffness

· Rolling body from INA

· Guide rails are coated with Teflon

Table:

· Precision ball screw spindle (Germany Rexroth) drives the X axis

· B-axis uses a high-precision double pinion to eliminate transmission play and ensure transmission accuracy

· Glass measuring rods with high accuracy - (HEIDENHAIN)

· Angle encoder (HEIDENHAIN)

· B-axis with powerful hydraulic clamping

· B axis of rotation includes: servomotor, worm gear, double pinion and transmission structure.

Drive system:

· High-precision C3 ball screw drive from Rexroth, the double nut is prestressed and ensures high accuracy

· Imported synchronous belt drive - ensures robust drive power

· Couplings of KTR (FRG) for maximum reliability

Further technical data and accessories, according to the appendix.

We have this machine in stock and available at short notice. Ask us about it! The travel costs for the visit will be charged to you at the time of purchase.

Benefit from the favorable leasing and hire-purchase conditions of ABC Leasing. Ask us about it. Of course, you also receive from us free delivery, assembly / commissioning and ready-to-hand transfer as well as control training.

Fig. Shows FB-130.

linear scales

CNC controls from

tool measuring system

workpiece measurement system

CNC-rotary table

milling and boring equipment

different spindle motor power

different kind of milling heads

increasing axes travel

bigger working table

Contact seller

GK Werkzeugmaschinen GmbH

Lindenstr. 2164589 Stockstadt Phone: + 49 (0) 61 58/8 47 72Fax: +49 615886931